Electrical discharge Machining technologies (EDM)

Our EDM machining services ensure unparalleled precision, allowing for intricate and complex designs with tight tolerances. Whether you need prototypes or mass production, our precision engineering guarantees high-quality results.

Types of EDM Precision Technologies

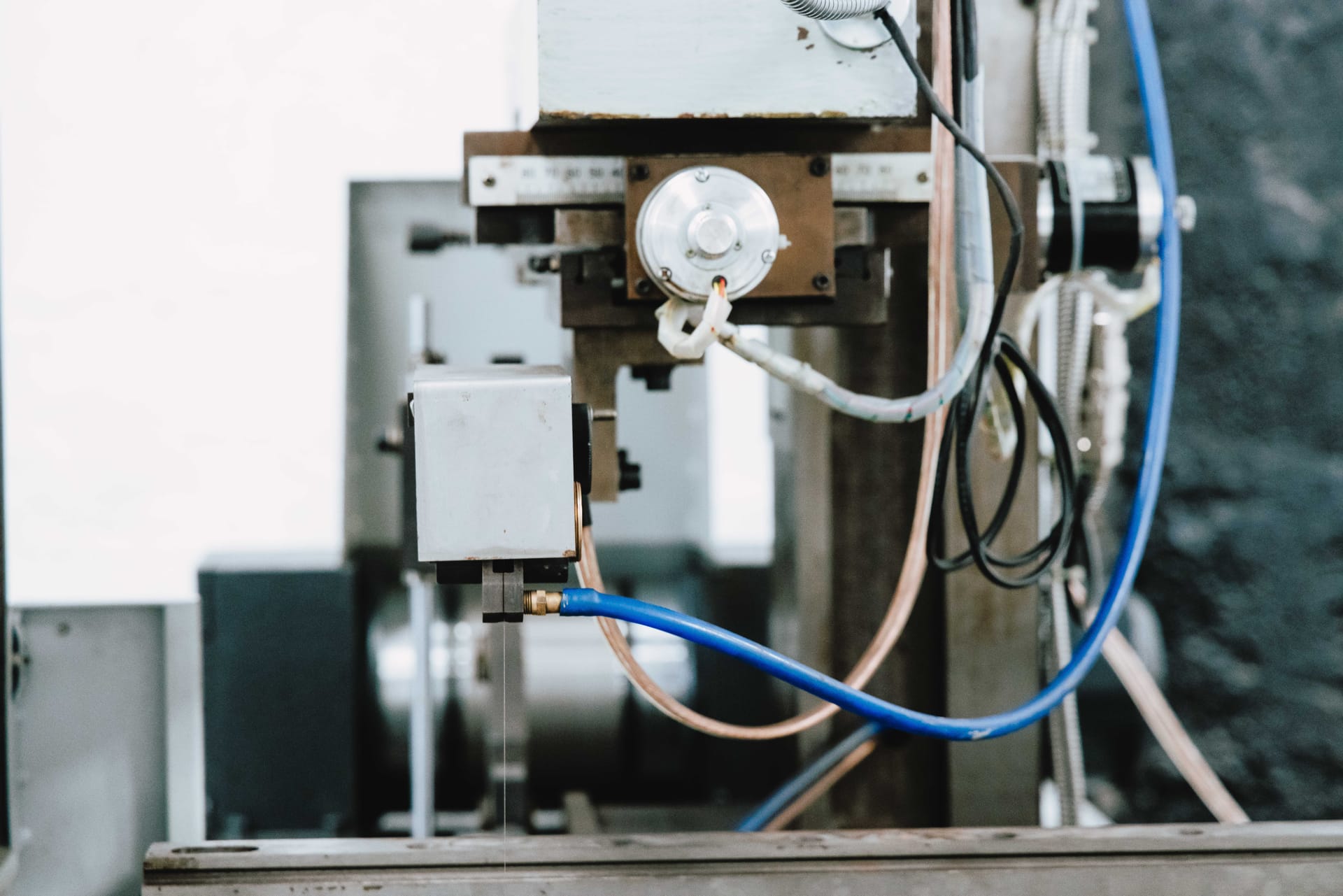

Wire EDM

Our Wire EDM services excel in creating precise cuts for intricate profiles with minimal material wastage, excellent surface finish. Wire EDM is ideal for projects requiring high accuracy and fine detailing.

Spark Erosion EDM

Spark Erosion EDM, also known as Ram or Die-Sink EDM, is perfect for creating complex 3D shapes and deep cavities in hardened materials. Our Spark Erosion EDM machines offer exceptional accuracy and repeatability for intricate molds and dies.

Difference Between Wire EDM and Spark Erosion EDM

In Wire EDM, a thin, electrically conductive wire is used as an electrode to cut through the material with precision. This process is ideal for intricate shapes and delicate components, offering high accuracy and excellent surface finish.

Spark Erosion EDM involves using a three-dimensional electrode and dielectric fluid to create spark discharges between the electrode and the workpiece. This method is suitable for creating complex 3D shapes, deep cavities, and hardened materials, making it perfect for molds and dies production.

Elevate Your Precision with Our EDM Machining Excellence

Unleash unparalleled precision and material versatility with our EDM machining services. Trust in our efficient processes and dedicated team for project success. Experience precision redefined.